Pare-chocs de quai de type V Résistance aux chocs élevée Durabilité longue durée Installation facile

Description

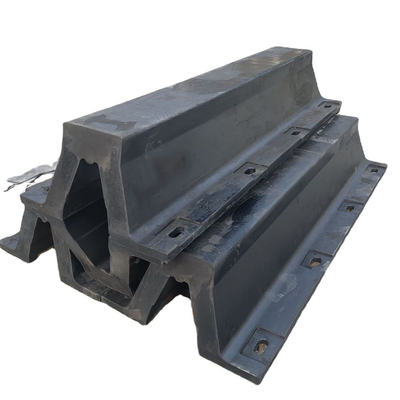

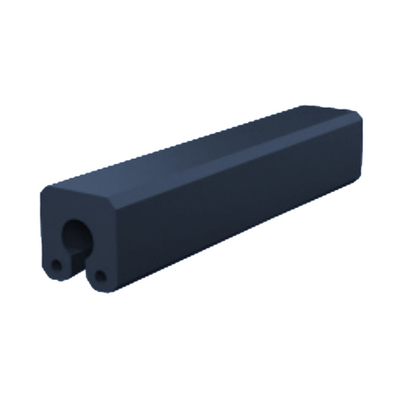

Le défenses en caoutchouc en arc est une solution de protection de quai haute performance conçue pour résister aux impacts d'accostage continus dans les environnements marins exigeants. Sa structure arquée en forme de « V » offre une courbe de déflexion de charge très efficace, permettant une absorption d'énergie supérieure avec des forces de réaction minimales sur le mur du quai. Construit à partir de caoutchouc de qualité marine supérieure renforcé de polymères synthétiques, il offre une durabilité et une fiabilité à long terme sous une contrainte opérationnelle constante.

Ce défense est un choix privilégié pour les ports, les terminaux et les chantiers navals qui recherchent un équilibre entre résistance, économie et efficacité de l'espace. Contrairement aux défenses cylindriques ou de type cellulaire, la conception compacte du corps de la défense en arc offre un excellent rapport performance/taille, ce qui la rend idéale pour les espaces d'accostage restreints et les projets de modernisation. La surface frontale lisse assure une répartition uniforme de la pression contre la coque d'un navire, réduisant le risque d'abrasion ou de dommages localisés.

Disponibles en tailles standard de 200H à 1000H, les défenses en arc Hongruntong sont conçues pour répondre aux normes internationales de qualité et de sécurité, offrant des performances fiables pour toutes les classes de navires commerciaux, navals et offshore.

Étude de cas : Modernisation d'un chantier naval en Europe du Nord

Un grand chantier naval d'Europe du Nord, spécialisé dans la construction de navires offshore, avait besoin d'un système de défense robuste pour son nouveau quai d'armement. Les panneaux en bois existants se détérioraient rapidement, entraînant de fréquentes interruptions de maintenance et des éraflures de coque sur les navires achevés. Le défi consistait à mettre en œuvre une solution de défense capable d'absorber une grande énergie d'impact des navires jusqu'à 25 000 DWT tout en conservant des dimensions d'installation compactes.

Hongruntong Marine a fourni des défenses en caoutchouc en arc de type V1000H avec des plaques de support en acier intégrées et des coussinets frontaux en UHMW-PE. Chaque défense a été montée le long d'un mur de quai de 180 mètres, ancrée à la structure en béton armé avec des fixations en acier inoxydable. Après l'installation, le chantier naval a signalé une réduction de 45 % de la contrainte d'impact d'accostage et l'élimination complète des dommages de surface de la coque pendant les opérations d'accostage.

Après deux ans d'exploitation, les défenses n'ont montré aucun signe de fissuration ou de fatigue du matériau, et les intervalles d'inspection ont été prolongés de trimestriels à annuels. Le projet a validé la capacité de la défense en arc Hongruntong à fonctionner de manière fiable sous de lourdes charges opérationnelles tout en réduisant les coûts totaux de maintenance du cycle de vie.

Spécifications

|

Nom du produit

|

Défense en caoutchouc en arc

|

|

Matériau

|

Caoutchouc naturel, caoutchouc de silicone

|

|

Couleur

|

Noir, ou Personnalisé

|

|

Surface

|

Lisse

|

|

Taille

|

Hauteur

|

200-1000mm

|

|

Longueur

|

1000-3500mm

|

|

Toutes les tailles peuvent être personnalisées

|

|

Propriétés physiques

|

Teneur en polymère

|

100 % vierge

|

|

Température de fonctionnement

|

-50℃~240℃

|

|

Résistance à la traction

|

≥16 Mpa

|

|

Densité

|

90+/-5 pour 100 mm

|

|

Dureté

|

50-70 (shore A)

|

|

Allongement

|

≥400 %

|

|

Caractéristiques

|

1. Résistant aux hautes températures

|

|

2. Excellente résistance à la déchirure, à l'huile et au vieillissement

|

|

3. Résistant aux acides et aux alcalis industriels et bonne élasticité

|

|

4. Construit selon PIANC2002

|

|

Application

|

Terminaux polyvalents, rampes RoRo, terminaux de navires à passagers, barges

|

|

Modèle

|

W

|

B

|

F

|

C

|

H

|

|

[mm]

|

[mm]

|

[mm]

|

[mm]

|

[mm]

|

|

HM-ARF200H

|

400

|

320

|

145

|

128

|

200

|

|

HM-ARF250H

|

500

|

410

|

175

|

160

|

250

|

|

HM-ARF300H

|

600

|

490

|

225

|

196

|

300

|

|

HM-ARF400H

|

800

|

670

|

300

|

260

|

400

|

|

HM-ARF500H

|

1000

|

840

|

375

|

325

|

500

|

|

HM-ARF600H

|

1200

|

1010

|

450

|

390

|

600

|

|

HM-ARF800H

|

1600

|

1340

|

600

|

520

|

800

|

|

HM-ARF1000H

|

2000

|

1680

|

750

|

650

|

1000

|

Caractéristiques

Absorption d'énergie élevée et conception à faible réaction

L'efficacité géométrique du profil en arc assure une déflexion uniforme et une dissipation d'énergie contrôlée, protégeant à la fois les coques des navires et les structures des quais. Sa courbe de réponse à la charge linéaire empêche les pics de force soudains lors des accostages à haute énergie, ce qui le rend adapté aux opérations d'accostage fréquentes impliquant des tailles de navires variables.

Formulation de composé de caoutchouc de qualité supérieure

Chaque défense est fabriquée à partir d'un composé de caoutchouc spécialement développé, conçu pour une résistance à la traction, une résistance à la déchirure et une endurance environnementale élevées. La formule contient des agents anti-ozone et anti-vieillissement qui empêchent le durcissement ou la fissuration de la surface causés par une exposition prolongée aux UV et à l'eau salée, maintenant l'élasticité et la fiabilité même dans des conditions météorologiques extrêmes.

Système d'installation modulaire efficace

Les défenses en arc Hongruntong sont pré-percées avec des trous de montage standard, ce qui permet un alignement rapide et précis lors de l'installation. Le système modulaire s'adapte aux configurations verticales et horizontales, idéal pour les projets de modernisation et les nouvelles constructions. Les plaques d'acier intégrées et les boulons résistants à la corrosion assurent une fixation sûre pendant des décennies d'utilisation.

Performances améliorées avec des coussinets frontaux en option

Pour réduire le frottement de la coque et l'usure de la surface, des coussinets frontaux en UHMW-PE ou composites en option peuvent être intégrés au corps de la défense. Ces coussinets améliorent l'interface d'impact globale, offrent un contact plus doux et prolongent la durée de vie tout en minimisant les exigences de maintenance dans les zones d'accostage à fort trafic.

Applications

Terminaux portuaires et installations de vrac lourd

Utilisé pour protéger les murs de quai renforcés contre les impacts de grands navires lors de l'accostage. Convient aux terminaux pétroliers, aux postes d'amarrage de marchandises et aux quais polyvalents avec des opérations de chargement fréquentes.

Atterrissages de ferries et terminaux Ro-Ro

Assure un accostage en douceur et en toute sécurité pour les ferries et les navires roulier, en particulier lorsque l'alignement précis et la force de réaction minimale sont essentiels.

Chantiers navals et chantiers de maintenance

Idéal pour les postes d'armement et les cales de réparation où l'intégrité de la coque doit être préservée lors des opérations d'accostage et de lancement répétitives.

Pourquoi choisir Hongruntong Marine

Qualité éprouvée et conformité mondiale

Les défenses en caoutchouc en arc Hongruntong sont fabriquées selon les normes ISO 9001 et PIANC, avec une conformité totale aux codes de sécurité portuaires internationaux. Chaque défense est soumise à des tests de compression mécanique, à une vérification de la traction et à une évaluation du vieillissement accéléré pour garantir une fiabilité à long terme.

Innovation en matière de matériaux et de conception

Notre département R&D affine en permanence les techniques de mélange et de vulcanisation du caoutchouc afin d'améliorer la résilience, l'élasticité et la résistance à la dégradation environnementale. Grâce à des outils de simulation avancés, Hongruntong optimise la répartition des contraintes et le profil de déformation de la défense pour des performances supérieures en conditions réelles.

Ingénierie personnalisée pour des opérations maritimes uniques

Nous concevons et fournissons des systèmes de défense sur mesure basés sur des calculs spécifiques de l'énergie d'accostage, des classes de navires et des géométries de quai. Chaque projet est soutenu par des dessins CAO, des données de simulation FEA et des manuels d'installation détaillés pour garantir la précision des performances et la sécurité opérationnelle.

Assistance mondiale et service du cycle de vie

Hongruntong assure une couverture logistique mondiale, une disponibilité rapide des pièces de rechange et une assistance technique sur site. Nos équipes de service dédiées effectuent des inspections, des programmes de remise à neuf et des audits de performance du cycle de vie pour aider les clients à maintenir leur efficacité opérationnelle avec un minimum de temps d'arrêt.

FAQ

1. Quelles sont les tailles de défenses en caoutchouc en arc disponibles ?

Hongruntong propose des modèles standard allant de 200H à 1000H, avec des dimensions personnalisées disponibles sur demande.

2. La défense peut-elle être utilisée dans les climats froids ?

Oui, nos composés de caoutchouc sont testés pour leur élasticité et leurs performances à des températures allant jusqu'à -40 °C, garantissant une fiabilité dans les ports arctiques.

3. Les défenses en arc conviennent-elles aux quais flottants ?

Elles peuvent être utilisées sur des structures fixes ou semi-flottantes avec des cadres de montage ou des plaques de support en acier appropriés.

4. Quelle est la fréquence de maintenance recommandée ?

Des inspections visuelles tous les 6 mois suffisent. Des inspections mécaniques complètes peuvent être effectuées annuellement ou après des événements d'accostage extrêmes.

5. Hongruntong fournit-il des conseils en matière de conception ?

Absolument. Nos ingénieurs fournissent des conseils gratuits, des calculs d'énergie et une optimisation de la conception pour garantir une sélection et une installation appropriées des défenses.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!