Longue durée de vie des défenses, construction légère, installation facile

Description

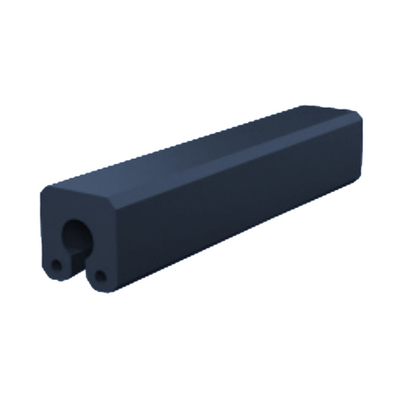

La défense flottante en mousse est une défense marine haute performance spécialement conçue pour les climats extrêmes et les applications d'ingénierie offshore. Construite à partir de mousse de polyéthylène à cellules fermées haute densité, enveloppée dans une peau en polyuréthane de qualité marine ou en caoutchouc synthétique, la défense offre une absorption d'énergie supérieure, une durabilité exceptionnelle et une flottabilité constante, même par mauvais temps, en conditions de gel ou dans des environnements UV intenses.

Conçue pour résister aux impacts d'accostage importants et aux forces continues des vagues et des marées, la défense maintient une faible force de réaction pour protéger à la fois les navires et les structures. Sa conception insubmersible élimine le risque de défaillance dans les opérations offshore critiques ou dans des environnements extrêmes. Le revêtement extérieur offre une résistance aux UV, à l'abrasion et à la corrosion, garantissant des performances à long terme et un entretien minimal.

Disponible en diamètres allant de 1 000 mm à 4 500 mm et en longueurs allant jusqu'à 5 m, la défense s'adapte aux navires, des petits bateaux de service aux navires de charge et offshore de 60 000 tonnes de port en lourd. Sa conception flottante et adaptable lui permet de fonctionner efficacement sur toute l'étendue des marées, en mer agitée et par mauvais temps, ce qui la rend idéale pour les plates-formes offshore, les parcs éoliens et les installations portuaires exposées. En réduisant l'impact des navires et les dommages structurels, la défense améliore considérablement la sécurité opérationnelle et réduit les coûts de maintenance globaux.

Étude de cas – Poste d'amarrage de parc éolien offshore

Dans un parc éolien offshore de l'Atlantique Nord, l'installation de défenses flottantes en mousse a protégé les navires de service et d'approvisionnement allant de 2 000 à 10 000 tonnes de port en lourd. Auparavant, les navires subissaient des rayures sur la coque et une usure des amarres de la plate-forme lors de l'accostage par fortes vagues et vents violents.

L'installation de défenses de 1 500 mm de diamètre et de 3 m de long a amélioré la sécurité de l'accostage, réduit la maintenance des navires et des points d'amarrage de la plate-forme, et maintenu des performances constantes à des températures inférieures à zéro, une forte exposition aux UV et des embruns salés continus. Les commentaires des opérateurs ont confirmé que les défenses offraient une protection fiable et une efficacité opérationnelle, ce qui les rendait adaptées à la réplication sur d'autres postes d'amarrage de service offshore.

Spécifications

| Nom du produit |

Défense flottante en mousse |

| Type de produit |

Défense flottante remplie de mousse à cellules fermées |

| Matériau du noyau |

Mousse de polyéthylène à cellules fermées haute densité |

| Peau extérieure |

Polyuréthane renforcé ou caoutchouc élastomère |

| Flottabilité |

Insubmersible, flottabilité positive |

| Absorption d'énergie |

Forte absorption d'énergie avec faible force de réaction |

| Résistance aux intempéries |

Résistant aux UV, à l'eau de mer et au vieillissement |

| Installation |

Montage par chaîne ou par support, personnalisable |

| Durée de vie |

15–20 ans dans des conditions de fonctionnement normales |

|

Diamètre x Longueur

|

Absorption d'énergie à 60 % de compression

|

Force de réaction à 60 % de compression

|

Poids approximatif

|

|

(mm)

|

(kNm)

|

(kN)

|

(kg)

|

|

300 x 1000

|

3.8

|

54

|

11

|

|

500 x 1000

|

10.6

|

91

|

41

|

|

600 x 1000

|

15.3

|

109

|

49

|

|

600 x 1000

|

18.3

|

131

|

55

|

|

700 x 1500

|

31

|

191

|

85

|

|

750 x 1500

|

36

|

204

|

89

|

|

900 x 1800

|

62

|

294

|

140

|

|

1000 x 1500

|

64

|

272

|

125

|

|

1000 x 2000

|

85

|

363

|

170

|

|

1200 x 2000

|

122

|

436

|

275

|

|

1200 x 2400

|

146

|

523

|

365

|

|

1250 x 2000

|

132

|

454

|

353

|

|

1250 x 2500

|

165

|

567

|

410

|

|

1500 x 3000

|

286

|

817

|

570

|

|

1500 x 4000

|

381

|

1089

|

720

|

|

1700 x 3000

|

367

|

926

|

700

|

|

1700 x 3500

|

428

|

1080

|

780

|

|

1800 x 3000

|

412

|

980

|

850

|

|

1800 x 3600

|

494

|

1176

|

965

|

|

2000 x 3000

|

508

|

1089

|

965

|

|

2000 x 3500

|

593

|

1271

|

1100

|

|

2000 x 4000

|

678

|

1452

|

1220

|

|

2400 x 4000

|

976

|

1743

|

1720

|

|

2400 x 4800

|

1171

|

2091

|

2140

|

|

2500 x 4000

|

1059

|

1815

|

1865

|

|

2500 x 5000

|

1324

|

2269

|

2500

|

|

2500 x 5500

|

1456

|

2496

|

2675

|

|

2700 x 5400

|

1668

|

2647

|

2865

|

|

3000 x 5000

|

1925

|

2750

|

3200

|

|

3000 x 6000

|

2287

|

3268

|

3740

|

|

3300 x 6500

|

2998

|

3894

|

4735

|

|

3600 x 7200

|

3953

|

4706

|

5800

|

|

4000 x 8000

|

4522

|

5809

|

8700

|

|

4200 x 8400

|

6277

|

6405

|

10000

|

|

4500 x 9000

|

7720

|

7353

|

10700

|

Caractéristiques

Résistance aux climats extrêmes

Le noyau en mousse et le revêtement extérieur sont conçus pour résister à des températures allant de -40 °C à +80 °C, à l'exposition aux UV, à la glace et aux fortes pluies sans perdre leur intégrité structurelle ni leurs performances d'absorption d'énergie.

Absorption d'impact élevée et faible force de réaction

Le noyau en mousse haute densité dissipe uniformément l'énergie d'impact, réduisant ainsi la contrainte maximale sur les coques et les structures offshore. Cela permet un accostage sûr pour les navires offshore lourds et les navires de transport d'équipement sans force excessive sur les points d'amarrage.

Durabilité à long terme et résistance à la corrosion

La couche extérieure en polyuréthane offre une excellente résistance à la corrosion par l'eau salée, à la prolifération marine et à l'exposition aux produits chimiques, garantissant une durée de vie de 15 à 20 ans, même dans des conditions marines extrêmes.

Conception flottante et adaptative

La défense s'adapte automatiquement aux fluctuations du niveau de l'eau et au mouvement des vagues, maintenant une couverture protectrice continue, ce qui est essentiel pour les plates-formes offshore, les ports exposés et les pontons flottants.

Applications

Parcs éoliens offshore et plates-formes pétrolières

Protège les navires de service, les navires d'approvisionnement et les bateaux d'équipage contre les impacts des vagues, les changements de marée et les intempéries.

Ports exposés et installations industrielles

Fournit une atténuation des impacts et une protection de la coque dans les ports confrontés à des courants forts, des vents violents ou des fluctuations de température extrêmes.

Postes d'amarrage offshore et de construction temporaires

Convient aux plates-formes flottantes, aux quais modulaires et aux zones de chantier offshore, assurant des opérations sûres dans des conditions environnementales exigeantes.

Pourquoi choisir Hongruntong Marine

Expertise en ingénierie des environnements extrêmes

Hongruntong Marine propose des solutions de défenses marines pour les conditions offshore et les intempéries, en intégrant des matériaux et des conceptions testés pour assurer une protection constante.

Solutions personnalisées pour les conditions difficiles

Nous fournissons des dimensions, des densités de mousse et des matériaux de revêtement extérieur sur mesure pour répondre aux exigences opérationnelles en cas de vents forts, de températures glaciales ou de fortes régions UV.

Longue durée de vie et fiabilité

Nos défenses sont fabriquées pour maintenir l'absorption d'énergie et la flottabilité pendant des décennies, minimisant ainsi les coûts de remplacement et de maintenance, même dans des conditions offshore extrêmes.

Support complet du cycle de vie

Hongruntong Marine propose des conseils d'installation, une évaluation des performances et une consultation technique pour assurer une fiabilité continue et une sécurité optimale pour les installations offshore et exposées.

FAQ

1. La défense peut-elle supporter des températures de congélation et de la glace ?

Oui, le noyau en mousse et le revêtement en polyuréthane sont conçus pour rester flexibles et fonctionnels à des températures aussi basses que -40 °C, assurant un accostage sûr dans les climats froids.

2. Est-ce adapté aux conditions de vagues et de marées élevées ?

Absolument. La conception flottante permet un ajustement automatique aux variations de marée et de vagues, maintenant une protection constante de la coque.

3. Quel entretien est requis pour une utilisation offshore ?

Minimal. Une inspection périodique est recommandée pour vérifier l'abrasion extrême, mais le noyau en mousse insubmersible assure une fonctionnalité continue.

4. La défense peut-elle protéger les grands navires de service offshore ?

Oui, elle convient aux navires jusqu'à 60 000 tonnes de port en lourd, offrant une excellente absorption des chocs et une faible force de réaction sur le navire et les structures du poste d'amarrage.

5. Quelle est la durée de vie prévue dans des conditions offshore difficiles ?

Avec une sélection appropriée, 15 à 20 ans, même avec une exposition à l'eau salée, aux UV forts, aux températures de congélation et aux chocs mécaniques importants.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!