Exceptional Energy Absorption Capacity per Unit

The volumetric efficiency of the pneumatic fender allows it to achieve a very high energy absorption capacity relative to its physical size and weight. This is a critical advantage in offshore logistics, where deck space and lifting capacity are limited. Our advanced design maximizes internal air volume and optimizes the compression curve to deliver one of the highest kJ/tonnage ratios in the industry.

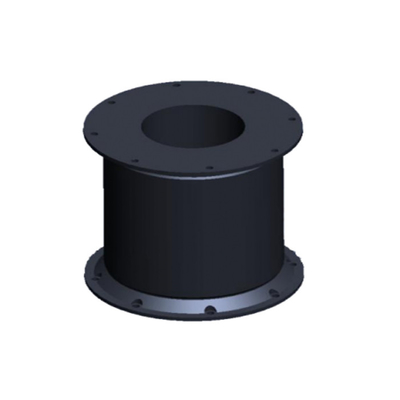

Outstanding Stability with External Bead Rings

A key differentiator for offshore use is stability. Our fenders are equipped with robust, integrally molded external bead rings. These rings act as anchors, significantly increasing the fender's resistance to rolling and twisting upon impact, especially at high deflection angles. This ensures consistent contact and load distribution, which is non-negotiable for protecting expensive vessel hulls and offshore structures.

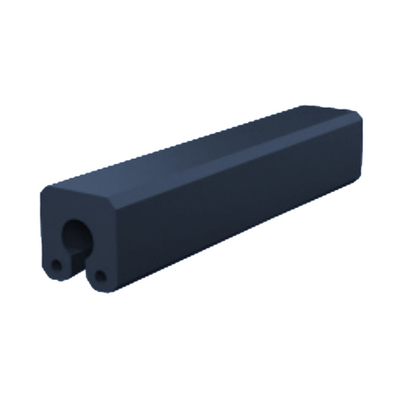

Superior Tear and Abrasion Resistance

We utilize a proprietary rubber compound with enhanced tear strength and high resistance to cutting, chipping, and abrasion. This is specifically engineered to withstand the harsh conditions of offshore environments, including contact with rough hull surfaces, debris, and prolonged UV exposure, thereby extending the service interval and reducing lifetime operating costs.

Integrated Lifting and Mooring Points

For safe and efficient handling, our offshore-grade fenders come with integrally vulcanized, high-strength pad eyes or lifting lugs. These are designed with a significant safety factor and are tested to handle the dynamic loads encountered during deployment, retrieval, and mooring operations, ensuring operational safety for crew and equipment.

Applications

Offshore Heavy Lift and Construction Operations

Essential for cushioning heavy-lift vessels during the loading/unloading of massive structures like oil & gas modules, offshore wind turbine components, and other outsized cargo where contact forces must be meticulously controlled.

STS Operations for LNG and Crude Carriers

The high energy capacity and stability are crucial for the safe side-by-side mooring of large LNG carriers and VLCCs during cargo transfer. The fenders prevent hull-to-hull contact that could lead to catastrophic consequences, ensuring the integrity of the cargo containment systems.

Floating Dock and Barge Fendering

Used as primary or secondary fendering on the sides of floating docks, repair quays, and large barges, providing a resilient and high-capacity buffer against berthed vessels, even in fluctuating tidal zones.

Why Choose Hongruntong Marine

Unmatched Expertise in Offshore Grade Solutions

We specialize in engineering fenders for the most challenging offshore applications. Our team possesses deep domain knowledge of the unique loads, environmental factors, and operational protocols of the offshore industry, which is reflected in our product design and technical advisory services.

Custom Engineered Solutions for Non-Standard Challenges

We recognize that many heavy-lift and offshore projects are unique. We have a proven track record of designing and manufacturing custom fender solutions, including non-standard sizes, special rubber compounds for extreme temperatures, and integrated accessory systems to meet specific client and project requirements.

Robust Global Logistics and On Time Delivery Promise

We understand that project delays in the offshore sector are costly. Our streamlined logistics and project management ensure that your fenders are delivered on schedule, anywhere in the world, coordinated to meet tight project timelines and vessel availability windows.

Competitive Value Proposition without Compromising Quality

By controlling our manufacturing process and achieving economies of scale, we offer a premium, certified product that provides exceptional long-term value and reliability, reducing the total cost of ownership through extended service life and minimized downtime.

FAQ

Q1: What is the difference between standard and offshore grade pneumatic fenders?

A: Offshore-grade fenders feature enhanced construction: thicker rubber walls, higher-grade steel cord reinforcement, more robust bead rings, and superior anti-abrasion compounds to withstand the harsher mechanical and environmental loads of offshore operations.

Q2: How is the internal pressure of the fender monitored and maintained?

A: Fenders are supplied with a recommended initial internal air pressure. This can be checked with a standard pressure gauge via the integrated valve. For critical applications, we can install permanent pressure sensors for real-time monitoring.

Q3: Are your fenders suitable for use in extreme cold climates?

A: Yes, we offer special low-temperature rubber compounds that remain flexible and retain their physical properties at temperatures as low as -40°C to -50°C, preventing brittleness and cracking.

Q4: What is your warranty policy?

A: We offer a standard warranty against manufacturing and material defects, typically for 3-5 years from the date of shipment, subject to proper use and maintenance as per our guidelines.

Q5: Can you provide type approval certificates from classification societies?

A: Absolutely. We can provide certified copies of type approval certificates from major societies like DNV, LR, and ABS upon request, confirming the fender's compliance with international standards.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!